Chemical Pump

Horizontal chemical axial flow pump

Owns 8 patent technologies, the comprehensive performance of ZW axial flow pump ranks in top among all the local competitors in China. It is also known as chemical elbow pump, chemical propeller pump, evaporative circulation pump and forced circulation pump for brine/salt industry. It is a product of provincial achievement, and it gained the award of technology progress of China machinery industry. There are plenty of real sales achievements for every single specification from diameter 250 mm to 1600 mm. ZW axial-flow pump is widely used as forced circulation pump in the applications of big flow rate with low total head, for example: forced circulation evaporator, MVR water treatment, vacuum salt industry, aluminum oxide, sodium sulfate, chlorine-alkali, sugar making, seawater desalination... There are various materials available for our axial flow pumps, including stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

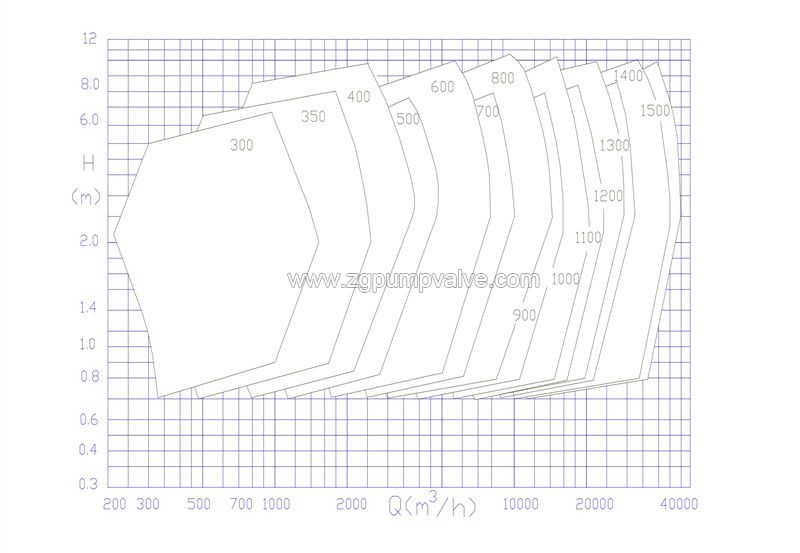

■Flow rate: Q=250~55000(m³/h)

■Total head: H=8~1.5 (m)

■Speed: n=180~1450rpm

■Fluid s.g.: γ ≤1.5

■Fluid temperature: T=0~180℃

■Fluid viscosity: ν ≤600(mm2/s)

■Pump diameter: Ф250mm~1800mm

■The impeller is high hydraulic efficiency type and is designed to be applicable to the requirements of evaporation system, it is able to adapt the fluctuation of evaporator loading, therefore reduces the energy consumption and increases the output.

■Adopting the adjustable impeller to fit different applications.

■Butt welding and thermal compensation reduces the investment cost.

■Low pump speed and low linear velocity reduces the damage of crystals.

■Pipe hung arrangement solved the stress compensation caused by heat expansion, no need of pump baseplate and expansion joint.

■Slight vibration, low noise, smooth operation, high efficiency and energy-saving.

■Elbow structure for pump body, piece-welded body and casted body for selection.

■Pump impeller is cantilever type with spherical hub, impeller blades are adjustable.

■Pump shaft adopts butt welding workmanship, the wetted parts or possible wetted parts are made from stainless steel or other corrosive materials.

■Mechanical seal and packing seal can be interchangeable.

■Adopting cartridge mechanical seal, reliable and easy for maintenance.

■Enlarged cylinder type bearing housing with oil level glass and oil filler, which extends the bearing life and interval of lubricant changing.

■Pump and be driven by motor through V-belts,gear box or directly through couplings. For pipe hung pump,the universal joint transmission must be adopted if the motor ≥200kW.

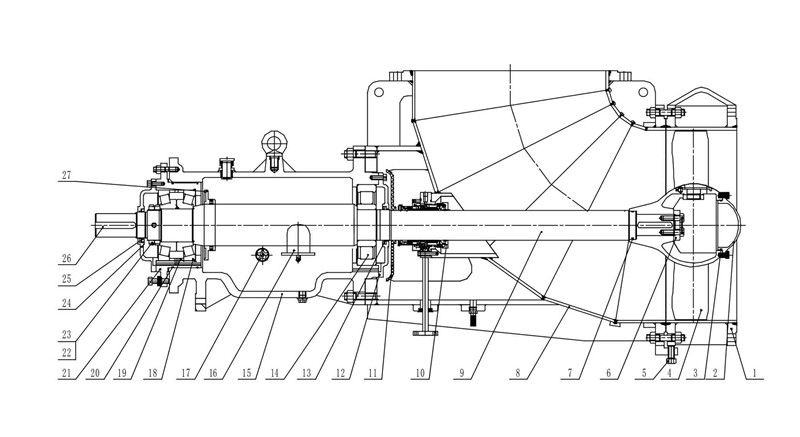

Structure drawing is as below

|

1. Casing 2. Impeller hub cover 3. O-ring 4. Impeller 5. Adjust bolt 6. Gland plate 7. O-ring 8. Elbow 9. Shaft |

10. Catridge mechanical seal 11. Water retaining ring 12. Front bearing cover 13. Skeleton oil seal 14. Front bearing 15. Bearing housing 16. Oil level gauge 17. Oil leveler 18. Rear bearing |

19. Bearing spacer 20. O-ring 21. Bearing box 22. Lock nut 23. Retaining gasket 24. Rear bearing cover 25. Skeleton oil seal 26. Key 27. Oil flinger |

|

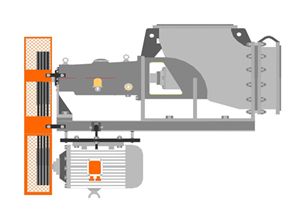

K-pipe hung arrangement No baseplate for both pump and motor,no expansion joint on pipe. Pump is driven by motor through V-belts.This arrangement is only applicable for the pump diameter from 300-500mm and motor capacity below 55Kw. |

|

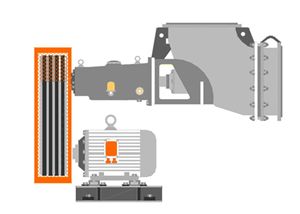

E-half pipe hung arrangement No baseplate for pump,pump is hung on the pipe,no expansion joint on pipe.For pumps above 700mm diameter,there must be a fluctuating frame at the horizontal pipe connecting the pump.Only V-belts and universal joint are recommended as the transmission method for this arrangement. |

|

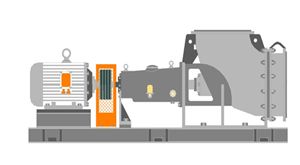

F-horizontal arrangement Baseplate is required for both pump and motor.An expansion joint on the pipe is also required for high temperature applications.Transmission methods can be V-belts and direct coupled. |

| For easy maintenance purpose,the above mentioned arrangements require a casing between horizontal pipe and pump. | |

| The name of material | The code name of materials | The name of spare parts | |||

| International standard | American standard | Impeller | Impeller cover |

Pump body (with casing) |

|

|

Corrosion resistant cast iron |

Aluminum cast iron gray cast-iron nodular cast iron Cr28 Cr30 |

C.I D.I |

● ● ● ● |

● ● ● ● |

|

| Carbon steel | Q235-A 23 25 |

A A36 WCA WCB |

● ● |

||

|

Stainless steel |

(ZG)00Cr18Ni10 | CF-3(SS304L) | ● | ● | ● |

| (ZG)0Cr18Ni9 | CF-8(SS304) | ● | ● | ● | |

| (ZG)0Cr18Ni12Mo2Ti | CF-8M(SS316) | ● | ● | ● | |

| (ZG)00Cr17Ni14Mo2 | CF-3M(SS316L) | ● | ● | ● | |

| (ZG)0Cr18Ni9Ti | CD-4MCu | ● | ● | ● | |

| (ZG)1Cr18Ni9Ti | Monel | ● | ● | ● | |

| (ZG)1Cr18Ni12Mo2Ti | ● | ● | ● | ||

| NO.20 alloy | ● | ● | ● | ||

| 1Cr13 | ● | ● | ● | ||

|

Duplex Stainless steel |

0Cr26Ni5Mo2 | (AlSi)329 | ● | ● | ● |

| 0Cr17Mn13Mo2N | ● | ● | ● | ||

| 00Cr18Ni5Mo3Si2 | ● | ● | ● | ||

| Anti-corrosion alloy | TA1、TA2、TA3 | Monel | ● | ● | ● |

| TA9、TA9-1 | H-B | ● | ● | ● | |

| TA10 | H-C | ● | ● | ● | |

| Ni-Resist1 | ● | ● | ● | ||

| Ni-Resist2 | ● | ● | ● | ||

| Ni-Resist3 | ● | ● | ● | ||

| Item | Factory standard | Optional configurations | |

| Motor |  |

Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  |

Reputed China brand | SKF, NSF, FAG or designated brands |

| Gear box |  |

Reputed China brand | SEW, Shandong Chenghua, Zhengzhou machinery instituteSiemens, Flender |

| Flanges&counter flanges |  |

China standard | European std, German std, American std, Japanese std |

| Couplings |  |

Pin type | Flexible diaphragm coupling |

ZW chemical axial flow pump is mainly applicable for the applications of big flow rate and low total head, like force circulation pump for evaporator systems:

■Salt-making force circulation pump

■Sodium sulfate force circulation pump

■Aluminum oxide force circulation pump

■Sugar-making force circulation pump

■Chlorine alkali force circulation pump

■MVR water treatment force circulation pump

Company video

-

+86 28 8218 1182

-

+86 28 8218 1182